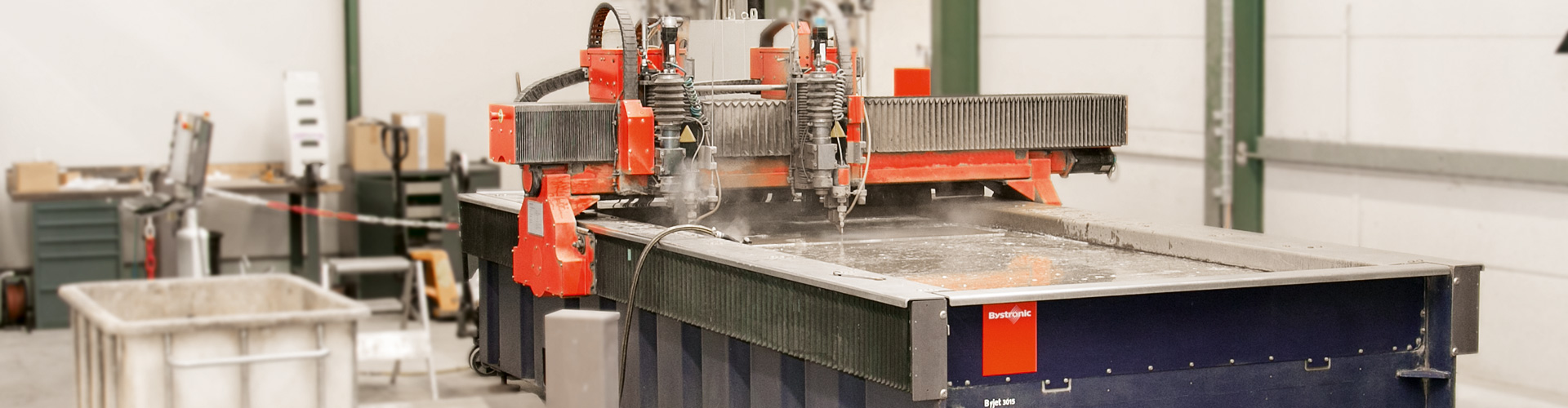

Water Jet Cutting

Water jet cutting is another great way to cut, in addition to laser cutting. The cold separation process broadens and complements the possible uses with lasers. There is a difference between abrasive cutting and pure water cutting.

With abrasive cutting, the pressure of the water is increased to 4,000 bar. It is mixed with a suitable abrasive agent and impacts the workpiece as a high-energy beam at great speed (550 to 900 m/s). It creates a uniform and clean kerf free from burrs.

With pure water cutting, soft materials are cut with a very fine jet of water - no abrasive agent - with a diameter of approx. 0.1 mm at a pressure of 3,000 bar.

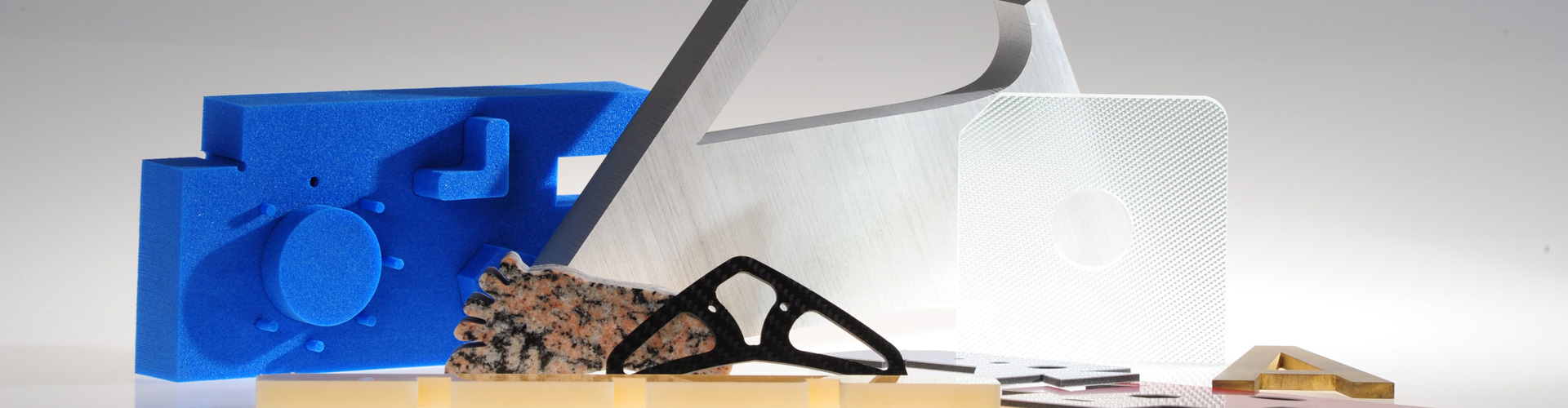

Range of materials: metal, ceramics, glass, stone, plastic, hard and soft foams, insulation and insulating materials, sandwich and structural materials, wood, paper, cardboard and sealing materials.