Forming

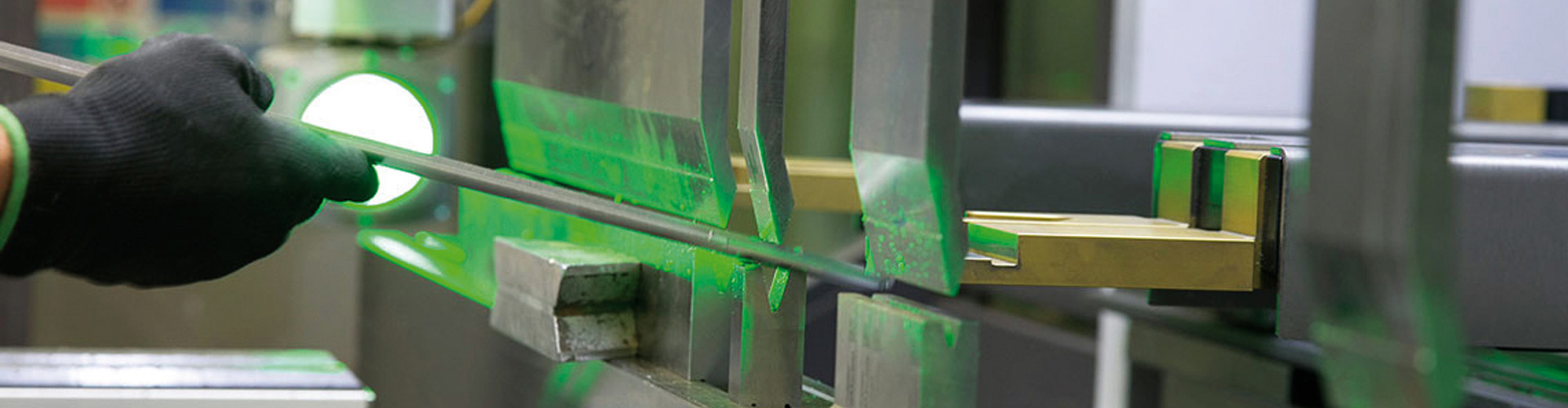

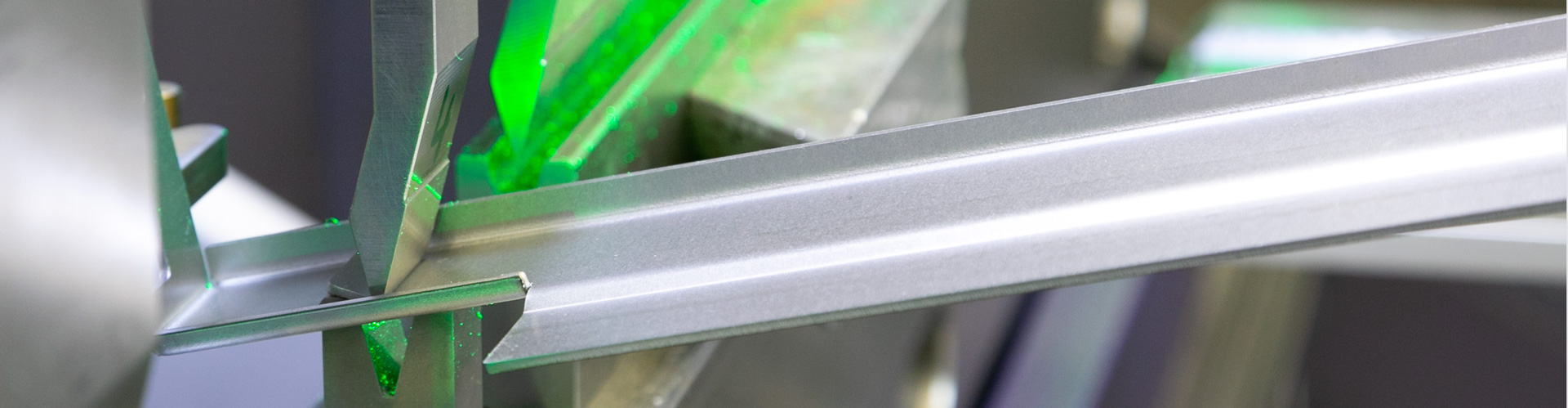

BLECHTECH AG's machinery also includes various benders, which can be used to process all kinds of parts in almost any size. The methods we use the most are air bending and embossing.

We are able to optimise set-up and throughput times and guarantee 100% reproducibility thanks to our computer-based programming using 3D models or STEP files. Our inventory of bending machines consists of 5 machines with bending lengths of up to 4,300 mm for sheets between 0.5 mm and 15 mm thick in any quality and quantity.

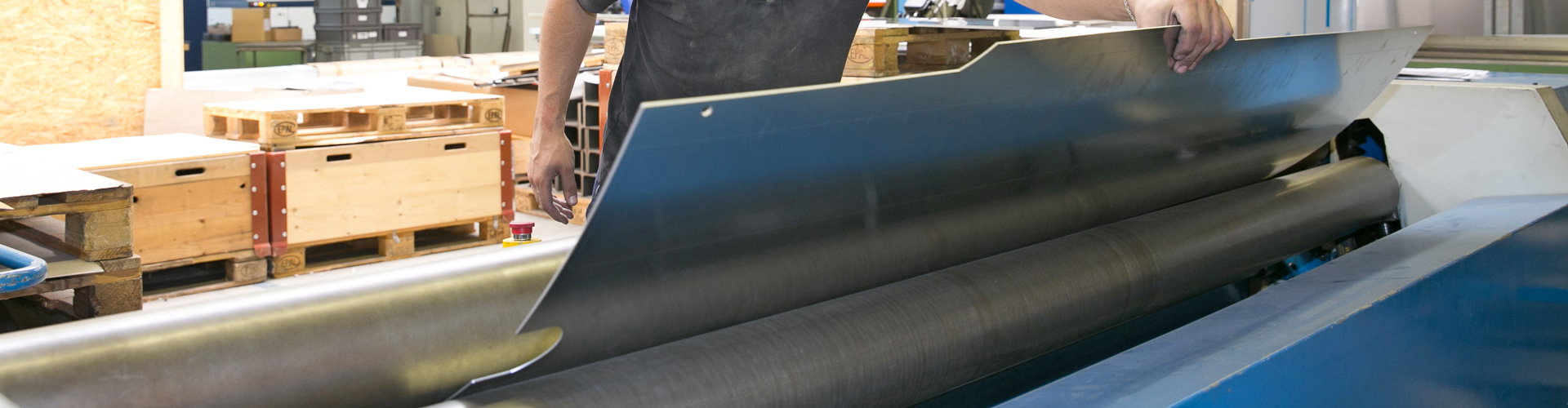

Fully automated Salvagnini bending centre

With medium and larger runs as well as complex sheet metal parts, we are still able to produce the parts cost-effectively and accurately in our fully automated bending centre. Thanks to short set-up times and high reproducibility, even small quantities can be folded cost-effectively.

We use swing folding beams as our tool. The workpiece is clamped between the upper and lower beam. With swing folding, we can produce similar profiles, e.g. by bottom bending. However the tool moves in a straight line.